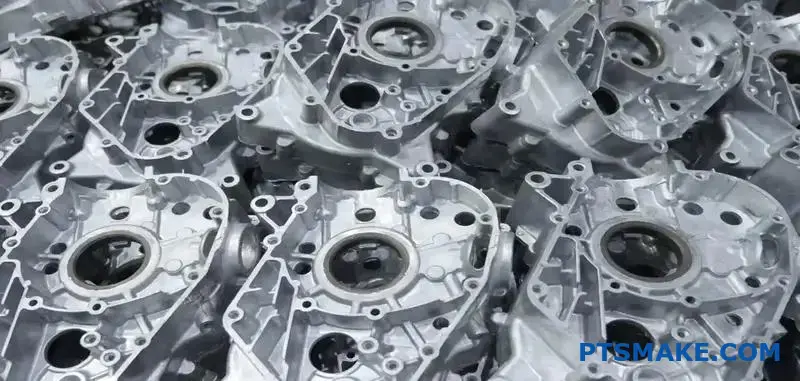

Discover the breakthroughs in Precision aluminum casting for modern industries

A Comprehensive Guide to Selecting the Right Factory Solutions for Your Project Demands

Selecting the right foundry solutions is important for the success of any type of job. Each spreading technique-- sand spreading, investment casting, and die casting-- has special advantages. Understanding these choices helps in making informed choices. Product option, production capabilities, and quality guarantee are key aspects to think about. In addition, evaluating costs can influence long-lasting viability. Precision aluminum casting. What aspects should guide this decision-making procedure?

Understanding the Various Sorts Of Factory Providers

While the world of foundry solutions might seem complex initially glimpse, recognizing the various types can considerably streamline the manufacturing procedure. Foundries normally focus on casting steels, and the main types include sand casting, investment casting, die casting, and centrifugal spreading.

Sand spreading involves creating mold and mildews from sand and is ideal for large parts or low-volume manufacturing. Investment casting, on the other hand, offers high precision for complex layouts, making it suitable for aerospace or clinical applications. Die casting, defined forcibly molten metal right into molds under high pressure, is effective for automation of smaller sized components.

Centrifugal casting uses rotational pressure to disperse liquified metal, generating solid, round elements. Each solution kind has unique benefits and is selected based upon details task demands. Comprehending these distinctions permits makers to pick the most ideal factory solution, eventually improving efficiency and product quality.

Secret Elements to Consider in Product Option

Selecting the ideal material for shop services is an essential action that influences the total success of a job. Secret factors in product choice consist of mechanical properties, thermal resistance, and rust resistance - Aluminum Casting Company. Recognizing the intended application and its requirements is vital; products should hold up against functional tensions while preserving integrity in time

An additional important factor to consider is the product's compatibility with the selected manufacturing process, as some materials are better fit for particular techniques. Cost-effectiveness also plays a significant role, as budget restraints can limit choices.

Schedule and lead times of materials can impact task timelines, making it needed for project supervisors to examine these variables completely. By thoroughly evaluating these components, one can guarantee a more effective and successful shop service experience.

Assessing Manufacturing Abilities and Technologies

Exactly how properly a shop can fulfill project specs depends upon its manufacturing capabilities and modern technologies. A thorough assessment of these aspects is important for project success. Production capacities encompass the factory's capacity to handle varying task dimensions, complexities, and timelines. Understanding the factory's equipment and machinery is crucial, as modern-day innovations such as computer numerical control (CNC) machining and advanced mold-making strategies can considerably improve precision and performance.

In addition, the factory's use of innovative products and processes, such as 3D printing or lost foam casting, can supply advantages relating to layout versatility and cost-effectiveness. It is additionally crucial to assess the shop's capacity to scale manufacturing, making certain that they can accommodate future rises popular without compromising top quality. By carefully evaluating these elements, task supervisors can make enlightened choices about which shop is ideal matched to fulfill their specific manufacturing needs and technical assumptions.

Value of Quality Control in Steel Spreading

Quality control stands as an essential column in the steel spreading industry, making sure that every part satisfies stringent specs and criteria. This process includes methodical monitoring and analysis of each stage of manufacturing, from first style to final examination. Executing Read Full Report rigorous quality control methods enhances the dependability and performance of cast parts, lowering the probability of issues that can jeopardize architectural integrity.

Efficient quality assurance cultivates count on in between customers and shops, as adherence to high requirements symbolizes dedication to quality. It additionally lessens pricey rework and hold-ups, enhancing manufacturing processes. By recognizing potential problems early, quality control not just safeguards completion product however likewise adds to constant renovation within the factory's operations. Inevitably, prioritizing top quality guarantee in metal spreading is essential for attaining client fulfillment and keeping an affordable edge in the industry.

Evaluating Cost-Effectiveness and Spending Plan Constraints

While going across the intricacies of foundry solutions, assessing cost-effectiveness and spending plan restrictions becomes an essential aspect for organizations. Comprehending the complete expense of ownership entails more than simply the first price; it requires an analysis of lasting costs, including materials, labor, and functional efficiencies. Companies need to request comprehensive quotes that outline all possible costs, enabling a more clear comparison in between various shops.

Furthermore, businesses should analyze their details project demands against spending plan limitations. This consists of examining the trade-offs in between lower expenses and potential influence on top quality, preparations, and dependability. It is crucial to take right into account whether the picked factory uses scalable options that can accommodate future needs without considerable monetary strain. By thoroughly balancing expense elements with job objectives, business can make informed decisions that enhance both budget plan and performance, guaranteeing successful end results for their factory tasks.

Regularly Asked Questions

How Can I Guarantee Timely Delivery of My Factory Task?

What Accreditations Should a Factory Company Have?

A respectable foundry company should possess accreditations such as ISO 9001 for high quality management, ISO 14001 for environmental administration, and industry-specific accreditations that demonstrate conformity with security and performance criteria pertinent to the casting procedure.

Can I Go To the Shop Before Choosing?

Yes, checking out the factory prior to making a choice is often a good idea. This enables possible clients to analyze the facility, satisfy the group, and assurance that the services line up with their particular project demands and requirements.

What Is the Common Preparation for Custom Castings?

The typical preparation for custom castings ranges from four to twelve weeks, relying on the intricacy of the style, material specs, and the foundry's capability. Prompt communication can typically quicken the process.

Exactly How Do Factories Deal With Layout Changes Throughout Manufacturing?

Shops generally suit layout changes throughout manufacturing by applying versatile procedures. They analyze the More about the author effect on timelines and costs, interact with clients, and change process to assure high quality while lessening interruptions to the production schedule.